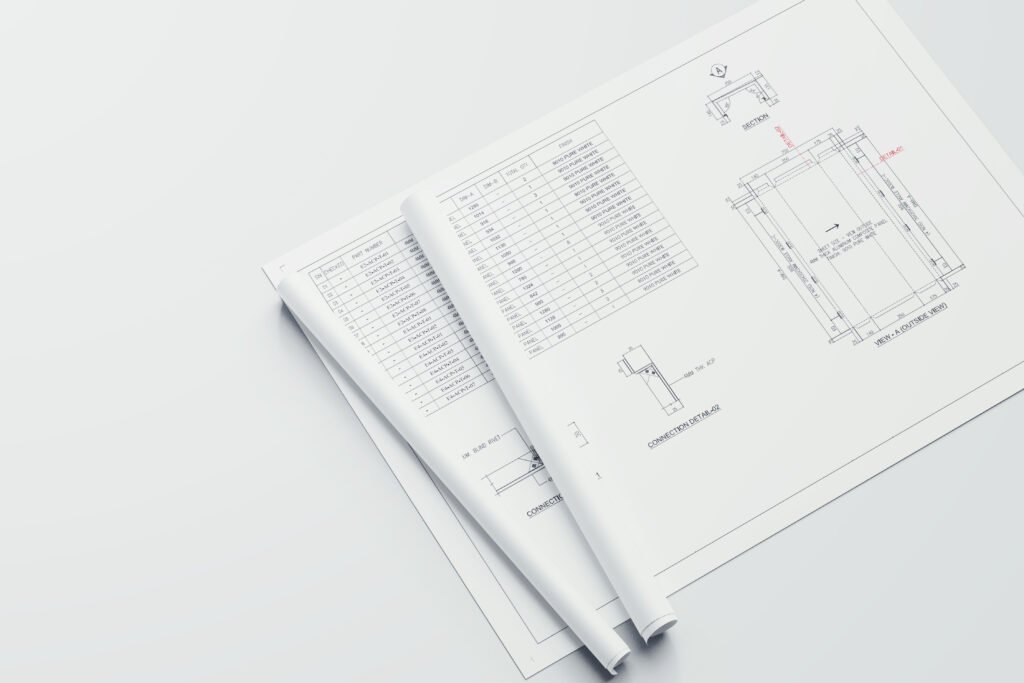

Fabrication drawings are essential for precision production, guiding the transformation of design concepts into physical goods. These detailed illustrations visually represent components, measurements, and specifications, ensuring accurate manufacturing of structures, machinery, and products. With meticulous attention to detail, these drawings bridge the gap between design intent and actual manufacturing, ensuring precision in every step.

What are fabrication drawings?

Fabrication drawings, also known as detail drawings, are technical drawings that contain specific information about the manufacture, assembly, and building of items or structures. This kind of drawings act as a communication tool for designers, engineers, and fabricators, providing extensive information regarding dimensions, materials, tolerances, and other fabrication requirements.

Types of Fabrication Drawings

Assembly drawings

This type of drawings are the basic blueprints that connect many components to form a coherent product. Assembly drawings are critical in fabrication drawing services because they facilitate collaboration between design and fabrication teams. These designs contain critical information about dimensions, materials, and assembly instructions, ensuring that the finished product is precise and of high quality.

Detailed Drawings

Detail drawings focus on specific components or sections, emphasizing complex details required for manufacture. Steel fabrication drawings rely significantly on precise drawings to convey dimensions, tolerances, and material specifications for each steel component. The fabrication process is guided by the attention to detail in these drawings, which ensures that design parameters are met.

Welding drawings

Welding drawings are vital in welding fabrication processes because they provide precise information on weld kinds, dimensions, and welding sites. Welding drawings in the steel fabrication drawing sector help to ensure structural integrity, safety, and industry compliance. These drawings help welders and fabricators create strong and durable welds.

Shop Drawings

Shop drawings connect design concepts to the manufacturing floor, providing comprehensive representations of objects designed for construction. Clarity in structural steel shop drawings improves manufacturing productivity and accuracy. Fabricators rely on shop drawings to guarantee that their products meet design criteria.

Cut Lists

Cutting lists optimize material consumption during the fabrication process by describing the dimensions and quantities of materials required for production. Cutting lists in the steel fabrication drawing sector educate fabricators on how to cut raw materials with the least amount of waste, hence increasing cost efficiency and sustainability.

What Makes Fabrication Drawings so important?

They are vital in manufacturing and construction, offering comprehensive information for fabrication and assembly. They ensure design accuracy, support cost estimation, aid in quality control, provide assembly instructions, list materials and procedures, ensure regulatory compliance, serve as documentation, and facilitate communication with stakeholders. These detailed drawings are essential for conveying design intent and maintaining precision throughout the production process.

In design and manufacturing, precise and comprehensive fabrication drawings are crucial because they act as blueprints for turning concepts into superior products. For fabrication drawing services, working with seasoned experts like CJ Facades guarantees precise and accurate drawings that creatively and precisely translate design concepts into reality.