I. Introduction to Shop Drawing

Hello there! Welcome to the wonderful world of shop drawing. If you’re new to this exciting, technical field, don’t worry, this guide is here to help you make sense of the basics.

1. Defining Shop Drawing: An Overview

Shop drawing, in the simplest terms, is a detailed plan or blueprint created by contractors or suppliers to indicate how a particular item or set of items will be fabricated or installed. It’s the core document used in the fields of construction and manufacturing to ensure that everything is built precisely to design specifications. Think of it like an instruction manual, but visually represented and filled with all the details a craftsman needs to create a high-quality end product.

2. Importance and Application of Shop Drawing in Construction and Manufacturing

This is not just a simple sketch or a rough draft. It is an integral part of many industries including construction, manufacturing, and engineering. It aids in ensuring accurate construction, helps in understanding intricate details of the design, facilitates communication among stakeholders, and significantly streamlines project execution.

3. The Distinction between Shop Drawing and Design Drawings

While design drawings convey the concept and aesthetics of a project, shop drawings take it a step further, breaking down the actual manufacturing or construction process. They are more detailed, technical, and provide a more nuanced understanding of the project.

II. The Crucial Components of Shop Drawing

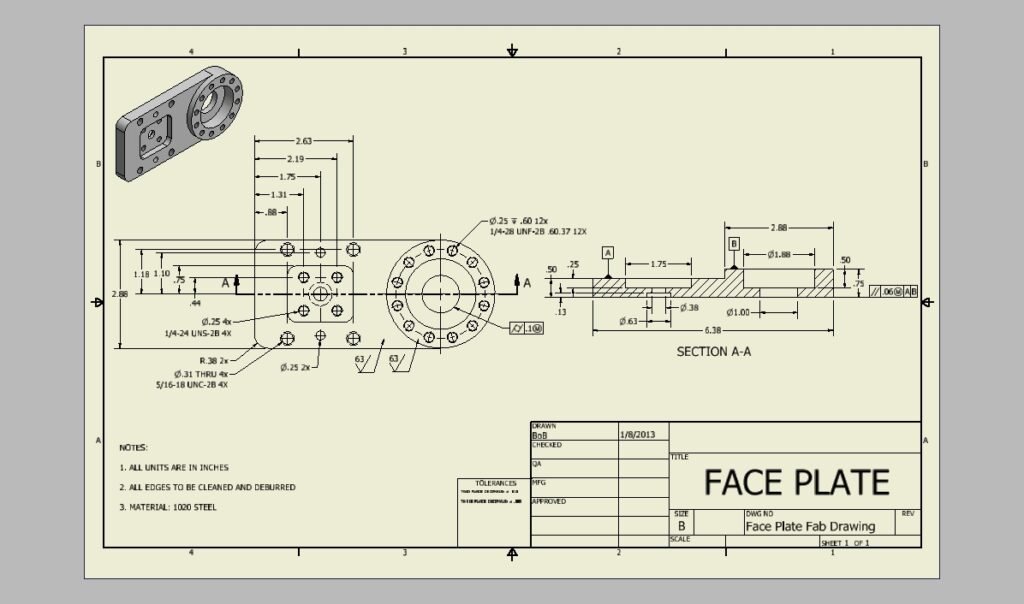

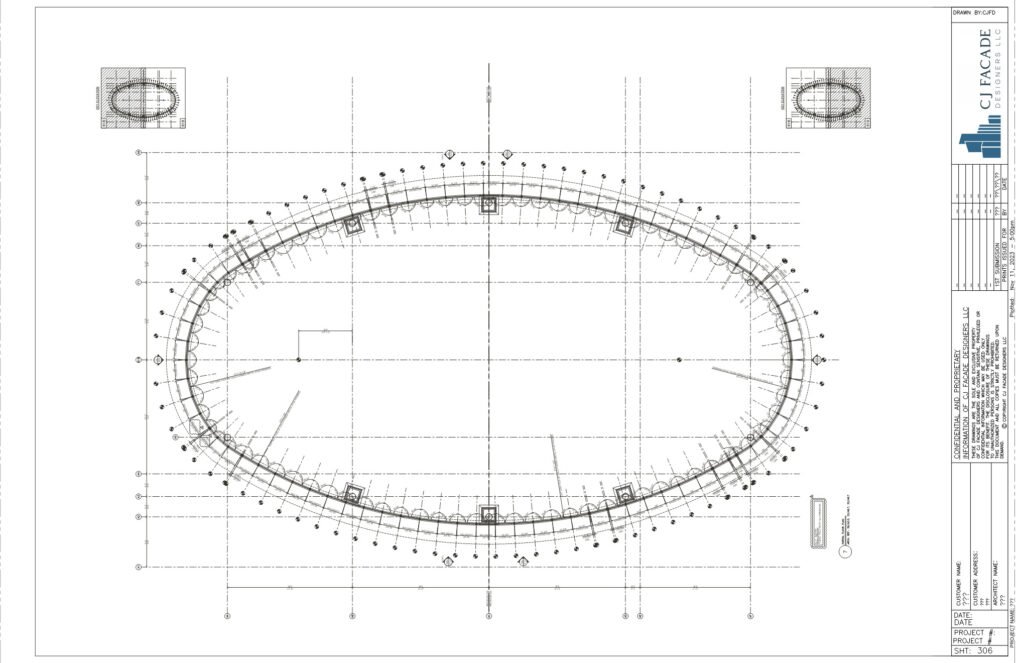

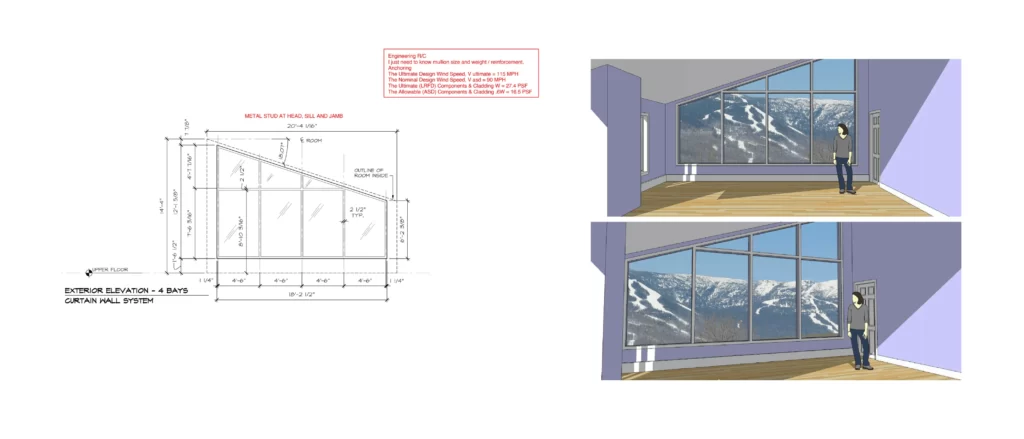

1. Detailed Specifications: Materials, Dimensions, and Procedures

One of the hallmarks of a proper shop drawing are its detailed specifications. Materials required, their dimensions, the procedures to be followed—all this and more are compiled in this blueprint of construction or manufacturing.

2. Representation of the Design: 2D and 3D Visualization

Be it 2D or 3D visualization, technical drawings present a comprehensive and realistic picture of the project outcome. From the placement and dimensions to the materials and finishes, every single detail is meticulously represented.

3. Auxiliary Documentation: Notes, Measurements, and Fabrication Details

No shop drawing is complete without additional supportive documents. These may include annotations to clarify the drawings, exact dimensions of the components, and specific fabrication and installation details.

III. The Process of Creating Shop Drawings

1. Preliminary Step: Understanding the Design Drawings

The first step in drafting a shop drawing is to thoroughly understand the design drawings. This includes studying all the details and revisions in the drawings and incorporating them into the shop drawing.

2. Creation of the Draft: Translating Design into Detailed Instructions

The next step involves the actual creation of the shop drawing. This means translating the essence of the design drawings into more detailed instructions that can guide the fabricators and installers.

3. Evaluation and Approval: How Shop Drawings are Assessed

The final stage involves inspection and validation of the shop drawings. This can be done by a team consisting of the project owner, architect, designer, engineers, constructors, and more.

IV. Roles and Responsibilities in Shop Drawing

1. Role of the Designers and Engineers

Designers and engineers usually provide the conceptual planning and structural details. They then collaborate to ensure the design conforms to the project’s requirements and standards.

2. Role of the Contractor and Subcontractors

The contractor, often with the help of subcontractors, translates the design documents into shop drawings. These documents provide precise details about how, where, and when each part of a project will be implemented.

3. Impact on Stakeholders

Educating stakeholders—everyone from project owners to construction workers—about interpreting and using shop drawings is important. This common understanding helps to ensure that all aspects of a project are carried out accurately and effectively.

V. Common Mistakes and Best Practices in Shop Drawing

1. Top Mistakes to Avoid in Developing Shop Drawings

Common slip-ups while creating shop drawings include assigning incorrect dimensions, incorrect material specifications, and overlooking pertinent details. Always double-check everything, as minor mistakes can lead to major on-site errors.

2. Tips for Efficient and Effective Shop Drawing

Dedication, thoroughness, and a keen eye for detail are your best friends here. Use visualization tools and softwares to enhance your drawing’s precision and detail. Remember, clear communication is crucial in creating effective shop drawings.

3. Case Studies: Successful Use of Shop Drawings in Projects

Through case studies of successful construction and manufacturing projects, it’s clear that detailed and accurate drawings serve as a cornerstone for optimal project execution. They improve coordination, reduce errors, and ultimately save both time and money.

VI. Conclusion: Recap and Key Takeaways

1. Importance of Mastering Shop Drawing

Shop Drawing is, without doubt, a critical skill in any construction or manufacturing project. The better you master the technique, the better your chances of a smooth, successful project outcome.

2. Benefits and Challenges in Creating Effective Shop Drawings

While this provide numerous benefits, such as better communication, precision, and fewer errors, they also present challenges. These may include the time and expertise necessary to create detailed and accurate drawings. Taking the time to learn and master this skill will undoubtedly pay off in the long run.

3. Concluding Remarks: The Path Ahead for Beginners

Remember, every skill takes time to master. So, stay curious, keep practicing, and never stop learning. The path to becoming a shop drawing expert is a journey, and every step forward is a step in the right direction.

VII. Frequently Asked Questions

1. What qualities should a good shop drawing possess?

A quality drawing must exhibit precision, detail, conciseness, and clarity. It should encompass essential specifications and maintain simplicity for easy comprehension..

2. How do I ensure accuracy in my shop drawing?

Ensuring accuracy involves meticulous efforts. Verify dimensions thoroughly, confirm correct sizing and positioning of elements, and utilize top-notch tools.